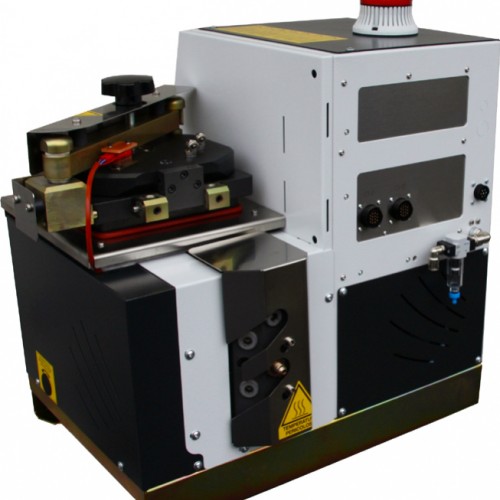

The new U8 Easy Series applicators for melt hot-melt adhesives made of polyamides and reactive polyurethane (PUR) are the top innovation on the international market for their simplicity of use, production flexibility, maintenance costs, quick installation, ease of safety standards, exceptional reliability and full integration with any packaging line, granting the maximum operational flexibility. The new microprocessor controls all those operations necessary to the system proper running: thermo-regulation in all different system areas, programming control of 8 glue tracks for each of the 4 independent channels. Additional features are: Economy Function, Clock, Weekly Program, Max. temperature alarm, Sequential Heating of all channels and delay Temperature Set Point lock.

HERMETIC MELTING TANK AND SAFETY LID

A large cylindrical, hermetically sealed loading inlet facilitates tank filling. The tank has a capacity of 8 kg. The tank lid is then blocked by a safety system that prevents it from opening involuntarily or accidentally, and also prevents material from spilling.

LCD DISPLAY

A new LCD display (specifically designed) graphically shows all the machine sections (tank, manifold, hoses and guns with respective parameters), allowing an immediate and extremely easy system programming also by unskilled operators, eliminating problems generated by codes and foreign languages to understand and meaning that the displays are all the same, independently of the country of use. A specific notification area controls the system status constantly and dynamically in all its operation phases. In case of eventual alarms or faults error messages are displayed.

INNOVATIVE PROGRAMMING

Another innovative feature of the new Easy Series is the "Rotary Switch": the selector through which it is possible, with extreme easiness, to program, modify and set section by section all those parameters intended for the system running.

GEAR MOTOR

The applicators are fitted with variable speed AC motors controlled by inverter positioned horizontally so as to have reduced overall dimensions and ease to access both for inspection and maintenance, thanks to a quick connector and to an easy to open body system.

GLUE FILTER

Easy to access and replace, it ensures a better distribution of the adhesive preventing the nozzle clogging due to the presence of impurities in the adhesive.

AIR DRYING SYSTEM

An innovative automatic air drying system (provided as standard and connected to the applicator with a quick coupling connector) removes the air from the tank and replaces it with inert gas or dehumidified dry air to prevent oxidation and thus prevent that the product react irreversibly, in a very brief time, upon contact with humidity in the air.

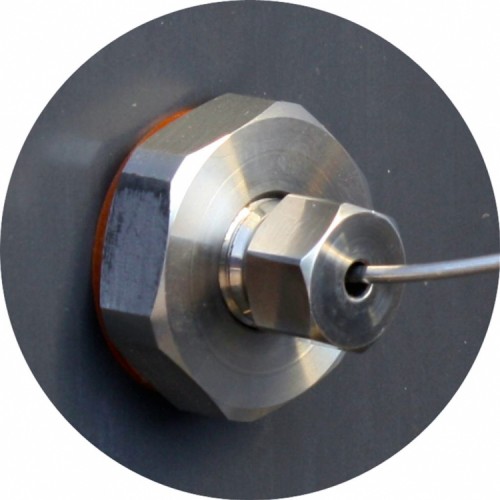

PRESSURE CONTROL DEVICE

A sophisticated control system shows on the applicator display the adhesive output pressure in the manifold. This visualisation is comparable to a traditional digital pressure gauge indicating the adhesive pressure in bar.

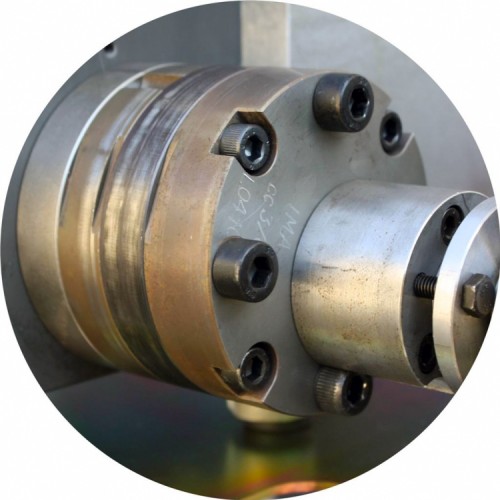

HIGH PRECISION GEAR PUMP

With the same dimensions it is possible to choose between gear pumps of different capacity. Absolute precision and reliability, they are made of super-quick steel and are fully hardened. Like all the inside parts of the applicator, also the pump is easy to remove in case of maintenance or replacement.

QUICK PRESSURE RELEASE AND REGULATION VALVE

It keeps the pressure set constant and ensures the utmost safety during the system use by and releasing the adhesive pressure into the system in an automatic and safe manner, even in the event of an emergency.

TUTKAL TİPİ : PUR ve PA 70000

TANK KAPASİTESİ : 8 kg

ERİTME KAPASİTESİ : 6 kg/saat

MAKSİMUM POMPA DEBİSİ : 14 kg/saat - 33 kg/saat

GÜÇ TÜKETİMİ : 4 kW

UYGULAMA SICAKLIĞI : 50°C-210°C (120°F-410°F)