MILLENNIUM SERIES M30 applicators are designed for melting and applying EVA, polyamide, polyester and high viscosity pressure sensitive adhesives. Invented for large scale production procedures, these applicators are available configured with a 30 kg tank and one or more high precision gear pumps. The pumps can be regulated at different flow rates to guarantee absolute precision under all operating conditions influenced by different product characteristics, including viscosity, temperature and typology. The new microprocessor controls all operations involved in running the system properly, such as thermoregulation in the different system areas and programming control of 8 glue tracks for each of the 4 independent channels. Additional features are: Economy Function, Clock, Weekly Program, Max. temperature alarm, Sequential Heating of all channels and delay Temperature Set Point lock. The innovative M30 melters are simple to use and flexible. Easy low-cost maintenance, quick installation, compliance with safety standards, exceptional reliability and full integration with all types of packaging lines also guarantee the highest operational flexibility.

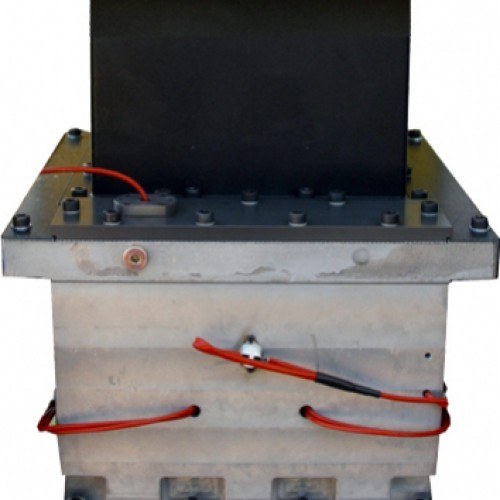

TANK WITH PROGRESSIVE MELTING SYSTEM

Large loading inlet open on three sides makes filling the 30 kg tank easier. Filling is done with the innovative progressive melting system, which eliminates problems related to carbonisation and oxidation, and optimises product results.

LCD DISPLAY AND INNOVATIVE PROGRAMMING

All parameters needed to run the system correctly are entered, programmed, modified and set very easily with the "Rotary Switch" selector. The new LCD display shows images of all machine sections with the respective parameters, making the system very easy to program, even for unskilled operators, because there are no problems with codes or foreign languages. A notification area monitors system status constantly and dynamically during all phases. Error messages are displayed in case of alarms or faults.

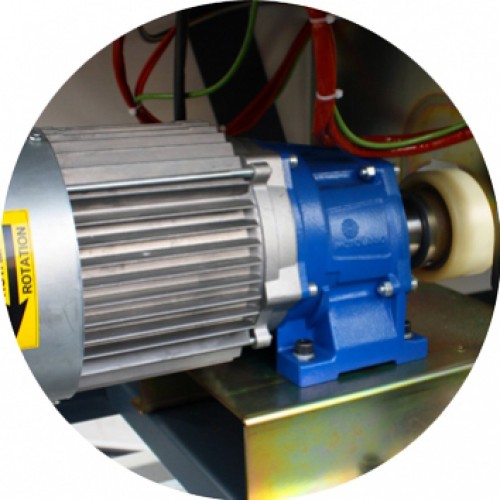

GEAR MOTOR

Melters have variable speed AC motors driven by inverters, positioned inside the electrical panel, and guided by a potentiometer installed on the machine. Motors are easily accessible for inspection and maintenance due to a quick connector and easy-to-open body system.

ACCESSIBILITY AND SURFACE TREATMENTS

Every part of the melter can be inspected easily by opening the practical body system. All parts in contact with the adhesive are coated with a high temperature resistant, scratch-resistant non-stick treatment in PTFE. This coating prevents glue from forming films, which could quickly become carbonised residue that would be very dangerous for the system.

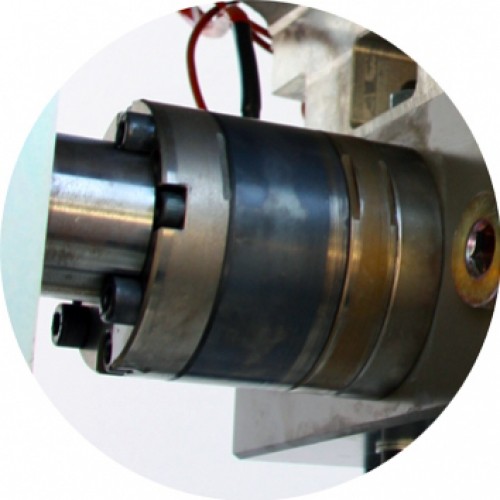

HIGH PRECISION GEAR PUMP

The melters are equipped with one or two high precision gear pumps with different flow rates (3-40 cc/rev under single or double flow). Both models are the same size. Pumps are absolutely precise and reliable, built of super-quick steel and fully hardened, and easy to remove for cleaning, maintenance or replacement.

GLUE FILTER

Easy to access and replace, the filter ensures a better distribution of adhesive and prevents nozzles from clogging due to impurities.

PRESSURE CONTROL DEVICE

A sophisticated control system shows the adhesive output pressure on the applicator display. This view can be combined with a traditional digital pressure gauge that shows the pressure of the adhesive in bars.

QUICK PRESSURE RELEASE AND REGULATION VALVE

Maintains the pressure at the amount set, and ensures the utmost safety during system use. Adhesive pressure is released into the system automatically and safely, also in the event of an emergency.

TANK CAPACITY: 30 kg

MELTING RATE : 30 kg/hour

HOSE&GUN CONNECTIONS : 2-4

MAX PUMP RATE : 4 kg/hour- 192 kg/hour

POWER CONSUMPTION : 5.7 kW

OPERATING TEMPERATURE: 50°C-235°C (120°F-455°F)